If you’ve ever wondered how an industrial punching machine works, you’re not alone. The majority of people don’t understand the process. This article will shed some light on the process and explain how the machines work. There are two types of machines: mechanical and electrical. Mechanical machines use compressed air to drive a piston to a spindle, which then creates an impulse that deforms the workpiece in a mould. Electrical punching machines include an electrical control part to further increase their efficiency.

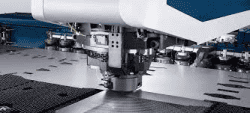

Modern CNC punching machines are automated, allowing them to produce a variety of workpieces in one cycle. They can also fold small tabs, punch sheared edges, and tap threads. This makes them incredibly productive within a component cycle time. They can also be programmed to generate various shapes and sizes, and can be highly customisable to match different workpieces. The process can be fully automated, and it’s a great benefit for any company that uses these machines regularly. For CNC Punching Machines, https://www.cotswold-machinery-sales.co.uk/euromac-bending-machines/punching-machines/

The most basic type of industrial punching machine involves a combination of mechanical and photoelectric devices. A ram or die press attaches to a circular stationary frame and pushes against the workpiece inside the die. The blanking die shears out a slug of sheet metal, making a blank for subsequent operations in the punch press, such as forming and drawing. Then the workpiece is expelled from the machine.

A crankshaft press is another type of punching machine. This type of punching machine is easy to construct and uses a crankshaft mechanism to convert rotary motion to linear motion. The connecting rod is connected to a flywheel to store energy during the idling period and deliver it to the shaft during the punching operation. A traditional crankshaft press is the same, but has a flywheel attached to the drive shaft.

The punching tool is driven into the workpiece by hydraulic pressure. The punching tool is then driven through the workpiece, leaving a hole in the shape of the die. Although industrial punching is often used on metal workpieces, it can also be performed on plastic. If the die is circular, the hole will be circular. Similarly, a triangular die will create a triangular hole.

A multitool industrial punching machine combines many different tools in one tool, making it suitable for small batch sizes as well as large lot sizes. This machine integrates ten different punches and dies, resulting in short tool change times and less machine downtime. It can process a variety of different parts, including sheet metal. These machines can process varying shapes, and have a large number of inserts to reduce setup and tool change times.